News

"World Premiere" at Interbrush 2016

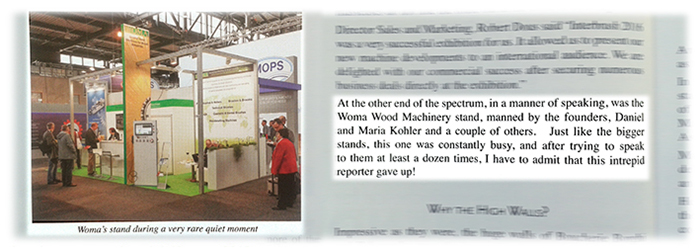

More than one hundred guest a day on only 18 sqare meters - businessmen from all over the world, customers who we already know since long time but also many new faces. As soon as the Freiburg fair opened its doors, the visitors scrimmaged on stand no. 4.4.11. A rush which makes the one and other reporter capitulating...

[brushware magazine July/August 2016]

[brushware magazine July/August 2016]

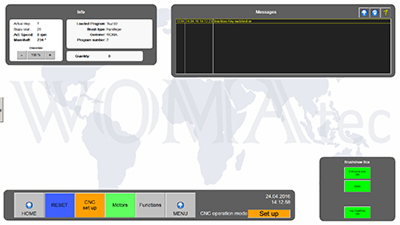

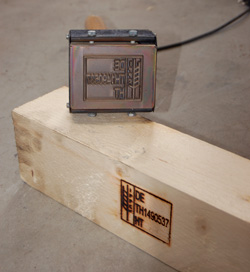

For the first time WOMA was showing an exhibit on their stand, a demonstration device of the new self-developed CNC control system. This is made to run old but still good brush drilling and filling machines and to avoid them from scrapping.

Meanwhile many brush producers have the same problem: They don't get spare parts or service anymore for their electronic systems because they are just overaged. "The develepment in this field is quite fast, faster than the mechanical worn on the machines." Daniel Koehler explains the dilemma. "The old controls are phased-out models and special components are scarce goods. Here we offer a flexible and low-cost solution." Ment is a complete overhauling of an available machine including mechanic revision, new pneumatic and electronic retrofit. Servo motors, controllers, modules and IPC of youngest generation - all standard components of popular manufacturers - are addepted to the condition of the machine and the individual requirements of each customer. The result is a machine as good as new but for about half of the costs of a new one.

"By the WOMA CNC control system we have the possibility to keep some old machines in production. That helps saving not only money but also ressources." Daniel Koehler sums up. The visitors were mainly responsive to the clear graphic, the simple menu navigation and the comfortable programming by the teach-in box.

But the great show innovation was the entrance of WOMAtec Maschinenbau GmbH. Daniel Koehler presented the in 2015 founded company for the first time and he already showed a few reference projects. Until now WOMAtec has build three strip brush machines, one double band strip brush machine with winder and various items for the paint brush produciton. The machines have been delivered to the United States, to South America, India and Germany. "Even our customers from America came to our stand just to tell us that they are really happy with the WOMAtec machines. This compensated all the hard work of the last months." is founder and owner Daniel Koehler glad to tell. The idea to build new machines besides dealing in second hand equipment came from his customers. Mainly strip brush machines and similar items for the production of technical brushes should be made. "But in principle we are a special machine builder, because each customer has special requirements. And even in this we would like to be different to our competitors, in taking care for the requirements individually and providing customized machines."

The target is to present a demonstration machine on the coming Interbrush. So it seems after Interbrush is before Interbrush...

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

In last year WOMA was able to do some investments again that will benefit both our employees and our customers.

In last year WOMA was able to do some investments again that will benefit both our employees and our customers.

This most important international fair for the brush industry takes place only every four years. Beside company owner Daniel Koehler also his wife and sales manager Maria Koehler have been there. Mr. Dmitry Volkov was taking care for customers from the Russian speaking countries.

This most important international fair for the brush industry takes place only every four years. Beside company owner Daniel Koehler also his wife and sales manager Maria Koehler have been there. Mr. Dmitry Volkov was taking care for customers from the Russian speaking countries.