Second Business: New Machines for Woodworking and Brush Industries

“Our baby needs a name” was the initiation for Daniel Koehler to found the new company “WOMAtec Maschinenbau GmbH”. He also wanted to separate the second hand machine trade business from the new machinery building.

But how was the idea born to build new machines for woodworking and brush industries? Daniel Koehler explains: “During selling a very old but solidly built strip brush machine our customer asked us if we may be able to build a similar machine for him: simple, mechanical, heavily constructed means strong but not so fast. With our current competences we felt quite able to do that. I was looking for a second business idea anyway so I decided to try it by receiving the input from our customer.” So the first machine was made still under the name of WOMA as a customized device. Further inquiries followed with different specifications. The team around Daniel Koehler was growing, also their knowledge, experience and qualifications. In May 2015 the new baby of brush industry was born. Daniel Koehler founded as 100% owner and only general manager the WOMAtec Maschinenbau GmbH.

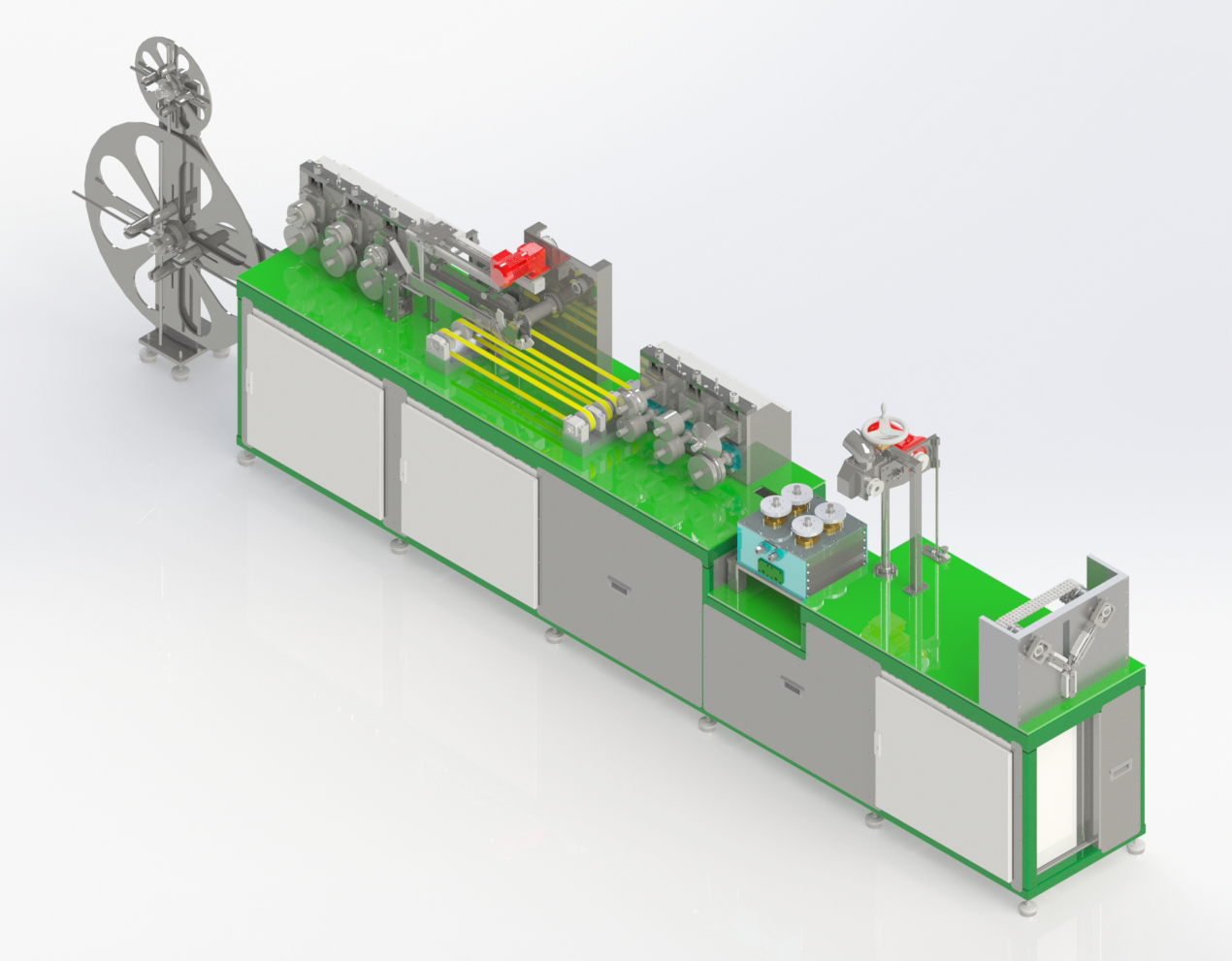

Until now three more strip brush machines were made, one double band machine with winder, two roller cutters, a paint brush cleaning machine and several small customized devices. “We are able to realize very different projects. Especially in the field of technical brushes customers are asking for particular solutions. Currently we are in progress with a fully automatic line for picking, fixing and insertion of abrasive filament bundles into glued brushes.”

Also the retrofits for brush drilling and filling machines are done under the name of WOMAtec. “Because at finishing such a full overhauling the machine is like new. We give warranty and we are supporting the new computer control system like a machine manufacturer.” Daniel Koehler explains. More and more second hand machines have old computer control system which are not supported anymore by the original manufacturer, but their mechanical condition is still good, sometimes even better than the lighter constructed new machines. So there is a growing demand. Like the WOMAtec machines also the software is simple and easy to operate. It’s compatible with all machine brands like Zahoransky, Schlesinger, Borghi etc. and suitable for up to 5 axis. There is also a WOMAtec software update for blister packing machines available.

Daniel Koehler by himself engineers the most machines and parts by himself. He pays attention to solid parts made of best quality steel, aluminum or special alloys for particular tools. The WOMAtec machines are consisting of worldwide available standard parts from German manufacturers like Festo, Siemens, SEW also of parts made by local suppliers or in-house at the common workshop with WOMA. “We can proudly say: Our machines are 100% made in Germany.” Daniel Koehler gives his resúmé.